Paul Lin shares his commitment to eliminating the earth’s plastic waste.

By Gabriella Lynn

Father of three, Paul Lin, is always shocked by the amount of waste his family produces. To promote a healthy and green lifestyle, Lin teaches his children to reduce their plastic waste. But the most important step is what happens after they clean and dump used plastic in a recycling bin.

Once the recycling bin is full, Lin collects his family’s plastic waste and takes it to his workplace to be transformed into diesel fuel. He has been doing this ever since joining Poseidon Industry, a company in Taiwan that specialises in recycling plastic waste, as a general manager in 2018.

“All my kids know what I do. My son even wrote an essay about what I do in terms of recycling and trying to help out the world,” he chuckles.

Having a green lifestyle is a big part of Lin’s vision for his family and himself because he cares about their surrounding environment. It is also why he decided to join the recycling industry.

“It’s kind of in my blood,” he says.

“All my kids know what I do. My son even wrote an essay about what I do in terms of recycling and trying to help out the world.”

Start of Something New

Born in Taiwan, Lin moved to the United States when he was young. He majored in studio art and minored in digital imaging at university, then worked at a printing house as a designer after graduation. But he left after eight months because he thought the job was boring.

In late 2000, Lin was inspired by a relative who was a real estate broker, and he became a broker himself. He continued working in the property business until 2011. He started a family in between those years and decided to move back to Taiwan to be closer to his parents. Lin launched a trading business that imports home goods from other countries in 2012.

“I never thought I would be doing recycling, real estate, or international trading business. I never had the idea and never thought this would happen back in (university),” he says.

When comparing the four jobs he has had so far, the 42-year-old says his current job is more complicated and requires more effort.

“I’m not (from) this background. I wasn’t a chemical engineering major so it’s really a challenge. I have to look for the kind of plastic we can treat. If a plastic is not recyclable or it has a bad (plastic-to-oil) conversion rate, then there’s no point in sourcing it,” he adds.

The Origin Story

Lin first started wondering about where trash was shipped to at his primary school cafeteria.

“After lunchtime, I saw people who took their trays and threw everything into trashcans, including food, milk bottles and plastic wraps. All these were just dumped into one trash can,” he says, shaking his head.

As he grew older, Lin kept on noticing how wasteful modern lifestyle is.

When working in the trading business, he witnessed excessive use of cargo boxes, shrink wraps, plastic straps and other sorts of packaging materials. Lin tried to minimise the amount of waste by reducing packaging and putting different products in one cargo box. This also helped to cut down on costs.

“I really care about what kind of environment we (live) in. If I can do something for human race, or at least for…Taiwan, that’s something I ought to do,” he says.

“I really care about what kind of environment we (live) in. If I can do something for human race, or at least for…Taiwan, that’s something I ought to do.”

Reverting Plastic to Oil

Lin’s company adopts a technology called pyrolysis that converts plastic back to its original state—petroleum.

The technology can convert 10 tons of plastic waste, sourced from factories and manufacturers, to 6,000 litres of fuel each day. The fuel is a mix of diesel, gasoline, and kerosene.

The company’s research department has recently discovered that single-use masks which are used globally to protect people from COVID-19, can be recycled into fuel as well. This can help solve waste problem caused by millions of disposed masks.

Lin also notes the increase in trash during the pandemic is choking the planet. “People are staying at home, so they always go online shopping. That probably saves time, but it creates more trash. The demand for cargo boxes (and plastic packaging) has increased tremendously,” he says.

“In today’s world, we want everything to be simple, easy and convenient, but we don’t see that being convenient actually creates more problems,” he adds.

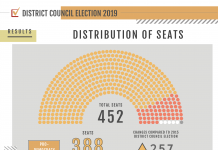

According to the Environmental Protection Association (EPA), a government agency for environmental conservation in Taiwan, the general recycling rate is 55 per cent. A 2017 report from the environmental consulting firm Eunomia notes that it is one of the highest rates worldwide.

Lin adds that Taiwan’s comprehensive recycling regulations make it easier to obtain suitable plastic for pyrolysis.

But he thinks that is not enough.

A study published on Science Advances in 2017 found that only about nine per cent of the world’s plastic was recycled, with the remaining 91 per cent either in landfills or incinerators. “(Plastic waste) is a problem beyond our capability. We just do the one per cent out of the 91 per cent. Without other people’s help, our contribution is nothing,” Lin says.

Working Hand-in-Hand

Lin urges people to work together to overcome the problem of plastic waste.

“If you take a step back to look at the whole picture, it’s not just your house, your neighbourhood, your city, or your country. We’re talking about this whole world!” he says.

Lin feels happy that more and more people are joining forces to help save the earth. People around him have all started to be more waste-conscious. They give Lin’s company plastic waste from their homes and offices, just like what Lin does for his own family.

Hoping his company can increase the plastic recycling rate in the coming 50 years, he vows to continue working in the recycling industry to make that happen.

“(The moment) I made a decision to join this company, I made a decision to make this company my entire career. This could be a career for life,” he says.

Edited by Patricia Ricafort

Sub-edited by Sarah Ryou